introduction

Hydraulic systems play a crucial role in many industrial applications, ranging from manufacturing machinery to construction equipment. The performance and longevity of these systems heavily depend on the quality of hydraulic oil. Contaminants such as dirt, water, and gases can degrade the oil, leading to increased wear, system inefficiency, and even failure. Hydraulic oil filtration systems are designed to address these challenges by removing impurities and maintaining oil cleanliness. This article explores the working principles, types, benefits, and maintenance of hydraulic oil filtration systems.

Importance of hydraulic oil filtration systems

Hydraulic oil contamination can cause serious problems in the operation of hydraulic equipment. Particulate matter like dust and metal particles can scratch and damage vital components such as pumps, valves, and actuators. Water contamination can cause corrosion, reduce lubrication, and promote the growth of microbes. Dissolved gases may lead to cavitation and loss of hydraulic efficiency. Hydraulic oil filtration systems help remove these contaminants, protecting system components, improving efficiency, and extending equipment life.

How hydraulic oil filtration systems work

Hydraulic oil filtration systems use several techniques to clean and purify hydraulic oil:

filtration

Oil is passed through specialized filters that trap solid contaminants. The filters can vary in pore size depending on the application and required cleanliness level.

dehydration

Using vacuum technology, water in the oil is vaporized and removed, which prevents corrosion and maintains oil performance.

degassing

Some filtration systems also remove dissolved gases, which improves the hydraulic oil’s insulating and lubricating properties.

By combining these processes, hydraulic oil filtration systems ensure the oil remains clean and functional for extended periods.

Types of hydraulic oil filtration systems

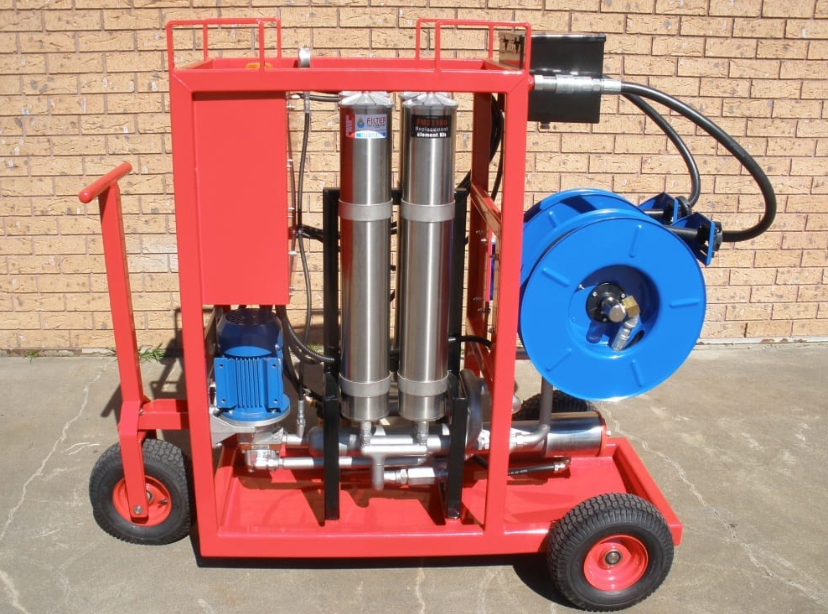

portable filtration systems

These are compact and mobile units ideal for on-site filtration, servicing smaller or medium-sized hydraulic systems efficiently.

stationary filtration systems

Typically installed in industrial facilities, these systems offer continuous filtration for large volumes of oil and support heavy-duty applications.

online filtration systems

Integrated directly into hydraulic circuits, online filtration systems operate while the equipment runs, continuously maintaining oil cleanliness without interrupting processes.

See also: Union Bank LBO Descriptive Test: Time Management & Writing Techniques

Benefits of hydraulic oil filtration systems

- increased equipment lifespan: Removing contaminants reduces wear and extends the life of hydraulic components.

- improved system reliability: Clean oil maintains consistent pressure and flow, preventing breakdowns.

- cost efficiency: Extending oil service life reduces maintenance and oil replacement costs.

- environmental sustainability: Reusing oil minimizes waste disposal and environmental impact.

- safety enhancement: Reducing contamination lowers the risk of system failures and accidents.

maintenance tips for hydraulic oil filtration systems

Proper maintenance ensures that filtration systems perform optimally:

- Regularly inspect and replace filters based on usage and contamination levels.

- Check vacuum pumps and degassing units for proper function.

- Inspect seals, hoses, and connections for leaks.

- Monitor hydraulic oil quality before and after filtration to ensure effectiveness.

- Train personnel on correct operation and safety procedures.

challenges and solutions

Handling heavily contaminated oil requires pre-filtration hydraulic oil filtration systems or staged cleaning to avoid clogging filters. Scheduling filtration during planned maintenance can reduce downtime. Investing in automated monitoring systems helps in early detection of oil quality issues.

conclusion

Hydraulic oil filtration systems are essential for maintaining the cleanliness and quality of hydraulic oil, ensuring the smooth and efficient operation of hydraulic machinery. By removing contaminants such as particles, water, and gases, these systems protect equipment, reduce maintenance costs, and support sustainable practices. Selecting the appropriate filtration system and maintaining it properly will significantly contribute to the reliability and longevity of hydraulic systems across various industries.