Introduction

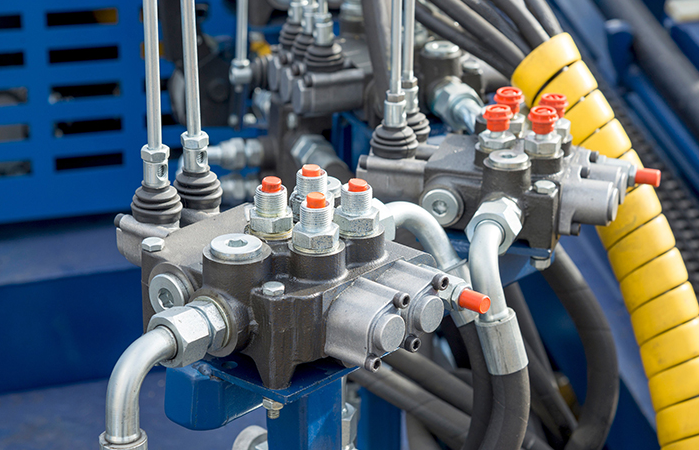

In the world of fluid power systems, hydraulic oil seals play a critical role in ensuring system reliability, operational efficiency, and equipment longevity. Designed to prevent fluid leakage and contamination, these seals are essential components in hydraulic cylinders and actuators. Whether in manufacturing, logistics, agriculture, or construction, the performance of hydraulic systems often hinges on the quality and compatibility of these seals.

Understanding the different types of hydraulic oil seals and their functions helps operators, engineers, and maintenance professionals make informed decisions when it comes to system design, troubleshooting, and repair.

What Is a Hydraulic Oil Seal?

A hydraulic oil seal is a mechanical component that prevents the leakage of hydraulic fluid within a system while simultaneously keeping out dust, dirt, and other contaminants. These seals are typically made from rubber, polyurethane, PTFE, or other durable materials that can withstand high pressure, temperature changes, and dynamic motion. Their primary function is to retain fluid and pressure within the working chamber of hydraulic equipment, thereby maintaining performance and safety.

Hydraulic systems use different types of seals depending on the motion involved—either static or dynamic—and the location within the system.

1. Rod Seals

Rod seals, also known as shaft seals, are installed in the gland of a hydraulic cylinder. Their job is to prevent hydraulic fluid from leaking outside the cylinder as the rod moves in and out. They operate under high pressure and are critical in maintaining the internal pressure of the system.

Key Functions:

- Prevent internal fluid leakage.

- Withstand pressure spikes.

- Enhance energy efficiency by sealing the fluid chamber.

Rod seals are often used in combination with wiper seals and buffer seals for improved performance in dusty or aggressive environments.

2. Piston Seals

Located inside the cylinder head, piston seals create a tight seal between the piston and the cylinder bore. They are responsible for ensuring that hydraulic pressure builds up on one side of the piston, creating the force necessary to move the rod.

Piston Seal Types Include:

- Single-acting piston seals (pressure on one side).

- Double-acting piston seals (pressure alternates sides).

These seals must be durable and resistant to extrusion, especially in high-load applications such as heavy equipment or industrial presses.

3. Wiper Seals (Scraper Seals)

Wiper seals are installed on the outer part of the cylinder where the rod exits. Their main job is to scrape off contaminants—dust, mud, or metal shavings—from the rod before it re-enters the system. This protects internal seals and helps extend system lifespan.

Why They Matter:

- Prevent seal abrasion and system contamination.

- Increase the life of rod and piston seals.

- Essential in outdoor or dusty work environments.

4. Buffer Seals

Buffer seals are used alongside rod seals to handle pressure spikes or fluctuations. They absorb excess pressure before it reaches the primary rod seal, thereby reducing wear and leakage.

Applications:

- High-speed or high-frequency systems.

- Heavy-duty industrial machinery.

- Systems prone to hydraulic shock.

5. Wear Rings (Guide Rings)

While not seals in the traditional sense, wear rings support the piston or rod, maintaining alignment and preventing metal-to-metal contact. This ensures even pressure distribution on the seals, reducing wear and improving sealing performance.

Benefits:

- Enhance seal efficiency.

- Minimize friction.

- Protect against scoring or cylinder damage.

See also: Optimizing Tech Talent Acquisition with Strategic Technical Interview Outsourcing

Material Selection and Its Impact

The performance of a hydraulic oil seal greatly depends on the material chosen for the application. Common materials include:

- Nitrile Rubber (NBR): Ideal for general-purpose sealing.

- Fluorocarbon (FKM/Viton): Resistant to high temperatures and chemicals.

- Polyurethane (PU): Durable and abrasion-resistant.

- PTFE (Teflon): Low-friction and suitable for high-speed applications.

Choosing the right material depends on factors such as temperature, fluid type, operating pressure, and motion frequency.

Top 5 Companies Providing Hydraulic Oil Seals

Here are five global leaders known for producing high-quality hydraulic oil seals:

- SKF Group – Offers a wide range of seals for industrial and mobile hydraulics.

- SabTech – Provides durable and precision-engineered hydraulic oil seals designed for demanding industrial applications.

- Trelleborg Sealing Solutions – Supplies advanced sealing materials and profiles.

- Freudenberg Sealing Technologies – Leading manufacturer of precision seals.

- Hallite Seals International – Specializes in fluid power and sealing technology.

These companies set global benchmarks for innovation, reliability, and material performance in hydraulic sealing systems.

Energy Efficiency and Infrastructure Applications

In industrial settings like warehouses, factories, or distribution centers, hydraulic seals are frequently used in door actuation systems. Understanding the role of seals in system reliability contributes to broader benefits, such as energy efficiency and reduced maintenance. For example, when integrated into entry systems, the key benefits of high-speed roll-up doors for industrial facilities include not only security and access control but also pressure retention and operational efficiency—both of which depend heavily on quality sealing components.

Conclusion

Hydraulic oil seals may seem like small parts of large machines, but their impact on efficiency, safety, and system performance is enormous. From rod and piston seals to wiper and buffer seals, each plays a distinct role in ensuring that hydraulic systems operate smoothly and without interruption. Understanding the various types of seals and their applications allows industries to better maintain machinery, reduce downtime, and increase equipment life.

Whether you’re managing a fleet of heavy equipment or designing systems for industrial automation, having the right knowledge—and the right seal—makes all the difference.